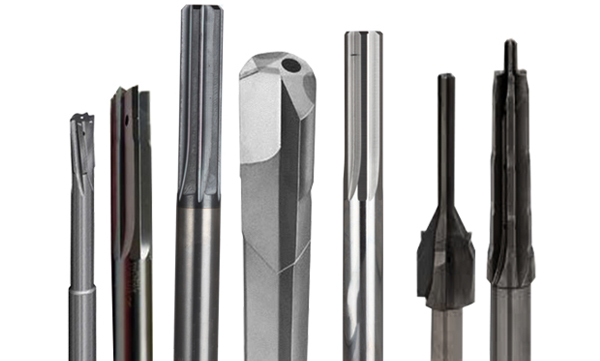

Solid carbide drills can be the safest option if you are looking for something that has great hole quality, manufacturing economy, and good process security. You can expect the best merger of accuracy and penetration rate that will be capable to achieve the IT8. Also, you can even recondition the solid carbide drills at the best cost-efficient rate. Some of the commonly types of solid carbide drills that we have for you include slot drills, twist drills, step drills, through coolant drills, extra long drills, burnishing drills, 3 flute core drills, micro and spotting drills, extra long drills, center and gun drills, and spade drills. Our company, Vega Tools, offers you a wide range of products that will promise you the finishing, high performance, high speed, and can be used for various generic purposes. In addition, you can expect extended life and best productivity. The solid carbide drills we offer have passed through all the tests to offer you one comprehensive solution. That means you can drill and chamfer on just one shot. The drills come with polished surface and they give you super evacuation when you provide low pressure coolant. We supply, manufacture, and even export the premium quality solid carbide drills that you can put to use in different areas. When you purchase these drills from us, you can be rest assured of the quality and the rates. We charge the lowest competitive prices and our drills will be with you for years, and that is our guarantee. To reach us out, you can email us your requirements or give us a call, and we shall be happy to help you out with anything you wish to have. Also, our staff will explain you about different features and applications of the products. We shall be waiting for you.

Send Message