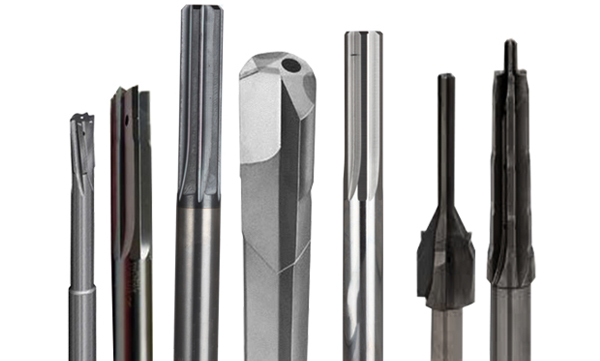

At Vega Tools, we bring you a premium range of PCD (Polycrystalline Diamond) Reamers that undergo rigorous quality testing to ensure unmatched performance and durability. Designed with precision and crafted using advanced technology, our PCD reamers meet the highest standards in dimensional accuracy, surface finish, and reliability. Our reamers are built to maintain tight tolerances on diameter, roundness, surface roughness, cylindricity, and concentricity—making them ideal for critical machining applications. Whether you require holder-integrated tools, chip breaker variants, or process-integrated solutions, we offer a wide range of options to suit diverse industrial needs. Key Features: High-precision reaming with consistent performance Suitable for multi-step drilling operations in a single pass Excellent performance in dry and semi-dry machining environments using water-soluble cutting solutions Capable of achieving cutting speeds of 300m/min and beyond Available in custom configurations, including stepped designs Applications: Our PCD reamers are widely used in: Resin molded components Spectacle lens machining Engine valve guide holes Automotive aluminum parts Aluminum die-cast alloy machining With Vega Tools, you’re assured of reamers that not only meet but exceed expectations. Choose precision, choose durability—choose Vega Tools’ PCD Reamers.

Send Message